What's the Difference Between SLS and SLM?

What's the difference between Selective Laser Sintering (SLS) and Selective Laser Melting (SLM)?

In SLM,powdered material is full melted ,whereas in SLS the powder is heated below its melting point (sintering). When laser heats the powder material to below melting point, it forms solid by fusion. The working principle is almost same in both printing method.

When to Use SLS and SLM?

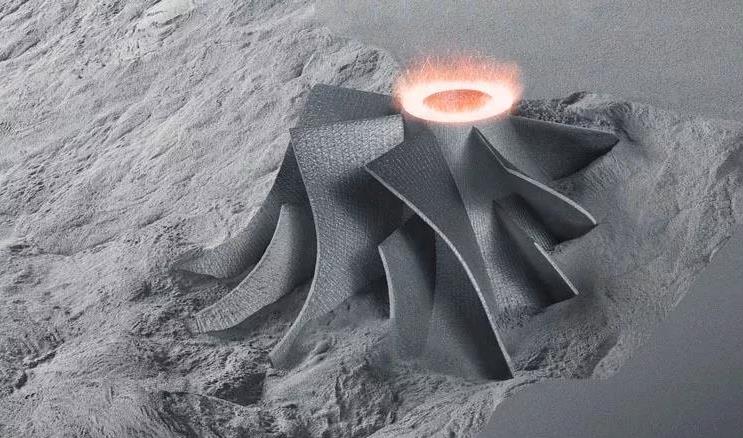

Because additive manufacturing works by building up layers instead of removing material, SLS, SLM and other 3D printing technologies are most useful for products with complex internal geometries like spiral vents and nested cores, or for rare metals that would be prohibitively expensive to machine. 3D printed metal can also be an effective option for manufacturing very small batches of metal parts or for projects with very short timelines.

In other cases, 3D printing metal is often substantially more expensive than CNC machining, especially for medium- to large-sized productions. Though it has longer lead times, machining is still quite cost-effective for small batches and becomes substantially less expensive at medium to high volumes. Moreover, metal machining yields superior fine detail and surface finish when compared to printed metal.

And sometimes we make the prototype injection mold with SLS or SLM , especcially for those small, discontinuous series of end products. Metal 3D printed dies have economic advantages in small batch production.